DiMuto and Intel partner up to power offline low-energy AI-enabled fruit quality control

AgriFood platform DiMuto is partnering up with Intel to supercharge its proprietary Product Quality Artificial Intelligence (PQAI) and DACKY hardware solutions.

This new alliance aims to empower warehouses to run advanced AI-powered quality checks without relying on internet connectivity, ensuring faster, more consistent, and more reliable produce inspections at scale.

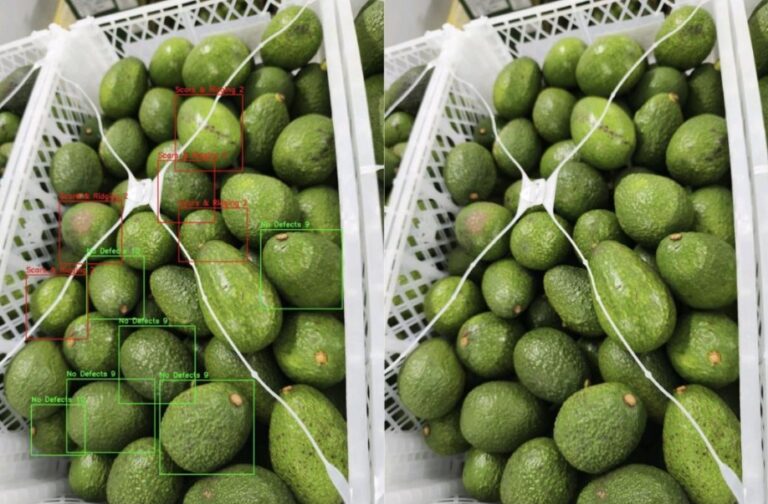

Powered by Intel Core Ultra processors and optimized with the Intel OpenVINO toolkit, the system delivers real-time AI image analysis for instant fruit defect detection, high-speed processing of carton scanning and photo capture, and advanced computer vision. This output is optimized for high performance with lower energy use.

“DACKY works hard, so you do not have to," said Jordon Ho, Head of Technology at DiMuto. "With Intel’s powerful processors enabling PQAI to run locally, we are proving that warehouse optimization is not just about efficiency. It is about giving buyers confidence, helping suppliers protect margins, and setting a new bar for trusted global trade.”

Accurate results even in low-connectivity settings

Built for seamless integration into existing packaging operations, DACKY transforms quality control into a streamlined, data-driven process that reduces waste, improves packing efficiency, and ensures buyers receive consistent, verified quality every time.

With the integration of DiMuto’s PQAI and DACKY system, every carton is digitally scanned, analyzed, and verified directly at source. By eliminating the need for Wi-Fi or constant connectivity, DiMuto enables localized AI processing, keeping fresh produce operations moving seamlessly, even in high-volume or remote trade environments.

Buy better, check better, and sell better

The Intel-powered platform enables importers and retailers to make smarter sourcing decisions with verified digital proof of quality. Real-time AI analysis ensures defects are flagged instantly and every carton receives consistent, objective quality scores.

Exporters benefit from reduced costly rejections, minimized disputes, and the ability to capture higher-margin opportunities with produce that is traceable and verified.

The AI revolution hits warehouses everywhere

The deployment of PQAI and DACKY into real-world warehouse environments underscores DiMuto’s role as a global trade specialist that uses technology to solve practical, everyday challenges in agri-trade.

“The Intel Core Ultra processors and OpenVINO toolkit deliver AI performance directly at the edge, enabling DiMuto's DACKY system to process complex computer vision tasks in real-time while reducing energy consumption and TCO compared to traditional solutions," said Michael Masci, vice president, Intel, Edge Computing Group.

The executive added that the collaboration showcases how Intel's optimization tools are empowering the next generation of agriculture.

By digitizing every carton and removing connectivity barriers, DiMuto and Intel are unlocking new opportunities for warehouses worldwide to run smarter, faster, and greener operations.

Related stories

DiMuto's new integrated agri-fintech ecosystem aims to revolutionize global food trade