JBT Marel is automating pineapple wax dosing methods

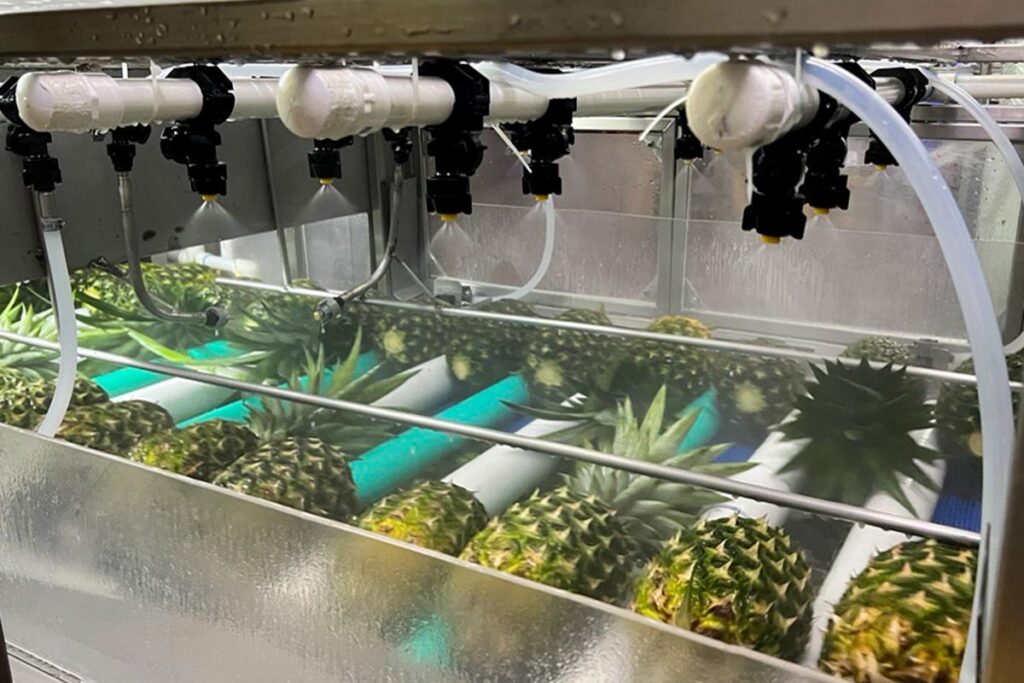

Through a press release, leading global packaging provider JBT Marel announced the launch of the ProDOSE™ Pineapple Wax Dosing Machine. The fully automated machine is designed to change the preservation process for large fresh pineapple producers.

The company claims the machine is a scalable replacement for outdated wax dosing methods and a new standard for brands committed to delivering top-quality fruit with greater efficiency and consistency.

Recognizing this innovation and ahead of its official launch, ProDOSE™ Pineapple won the Freshness Control Solution of the Year award at the 2025 AgTech Breakthrough Awards.

“The ProDOSE™ Pineapple takes what is typically an error-prone step in postharvest processing and automates it, solving a critical challenge for one of the most in-demand segments of the produce industry,” said Christina Campos, JBT Marel General Manager. “It’s a groundbreaking advancement that reflects our commitment to raising the bar for food safety, quality, and preservation while reducing manual effort and waste.”

An automated solution for an error-prone task

Wax dosing and concentration monitoring for fresh pineapples have traditionally been a manual process requiring labor-intensive recharging every 20 minutes. According to JBT Marel, this approach introduces the risk of human error, which can result in over- or underdosing of the wax solution. This can potentially lead to over-concentrated wax (and consequently, product waste) or under-concentrated coating, which risks spoilage before the fruit reaches its destination.

With the ProDOSE™ Pineapple, this task is now automated, ensuring each pineapple is coated evenly and consistently.

“Beyond consistency and efficiency, our ProDOSE™ Pineapple gives producers greater control and flexibility over the waxing process,” adds Fernando Edagi, Product Line Director for JBT Marel Fresh Produce Technologies.

The ProDose technology features a range of application settings, allowing operators to adjust for the specific post-harvest needs of different pineapple varieties and external conditions. The system also has real-time monitoring and data logging through a user-friendly mobile app, as well as wireless data transmission for seamless integration and accurate record-keeping.

Related stories

Project looks at impact of waxes on food safety

Apeel Sciences responds to Federal Labeling Bill

Five food trends and how they are shaping new safety requirements