Why ASTRA fruit peeling machines are so special

By ASTRA

Using an automatic peeler machine to replace manual peeling is a common trend. There are many types of peelers in the market, and although they all serve the same peeling purpose, the functionality, productivity and results can be very different. ASTRA Inc. is an innovative Japanese peeler developer. The company is famous for its unique ‘Peeler blade’ technology.

Multiple types of fruits and veggies can be peeled with ‘Blade Peeler’

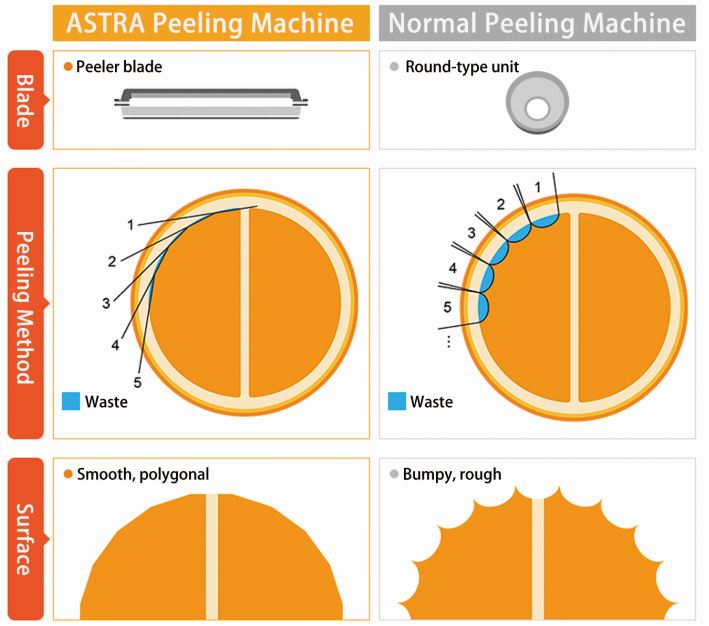

When peeling fruits with your hand, you will always use a hand peeler. Hand peelers can always peel beautifully. However, most of the traditional peeling machines don’t use the same blade of the hand peeler, they use a ‘round-type peeling unit’. This peeling unit cuts out small circular pieces around the edge until the fruit is peeled.

Though the round-type peeler serves basic functionality, it can result in high waste, slow speed and rough quality. To solve these issues, ASTRA developed a ‘blade peeler’. The principle shares similarities with manual peeling. The blade is straight, sharp and thin. When turning, the blade moves in a polygonal way, while always tightly pressed to the surface of the fruit.

More than 20 types of products can be handled with one single machine, including fruits such as orange, grapefruit, lemon, kiwi, and vegetables such as tomato, potato and turnip. Users only need to place the product on the rotation head, and press the start button. There is no need to worry that the product is in an irregular shape, as the machine has a mechanism to optimize the position of the blade and find the best angle to peel it.

Less waste and smoother appearance from ASTRA ‘Peeler blade’ - better peeling performance

Compared with traditional ‘round-type peelers’, the new ASTRA ‘blade peeler’ generates a variety of benefits with regards to peeling performance. First of all, the fruits’ peeling surface is much smoother than round-type peelers, which leave the pulp surface very bumpy and rough.

This results in low pulp waste and fewer juice drippings. Also because of the smoother surface, the fruit has a longer shelf life and can keep fresh for a longer period. Secondly, the straight blade performs faster with high accuracy, which results in better yield rate.

Most importantly, users can easily adjust the peeling depth and select the most suitable program for a certain type of fruit. No matter how wonky the fruit is, no matter how thick or thin the fruit peel is, from thick-skinned oranges to thin-skinned lemons, the blade peeler will provide the best performance accordingly.

One machine serves multiple types of fruits

Benefited by the blade peeler, a wide range of fruits and veggies with various features can be processed with the ASTRA peeler.

Irregularly shaped fruits

The irregular fruit shape challenges the peeling technique. Mangoes share the reputation of ‘most difficult fruit to be peeled’. Every mango can be different, from round to elongated shape. The highly-flexible blade peeler works perfectly on each fruit.

Thick skin fruit

Fruits such as pineapple have a barrel shape. A traditional round-type peeler can easily result in high waste. As the blade peeler moves in a polygonal way, the yield rate can be 50% higher than a round-type peeler.

Thin skin fruits

Sometimes you only need thin fruit skin for lemons and limes, when making drinks like Limoncello. Zesting can be done with the adjustable- depth blade, the thinnest fruit skin can be perfectly peeled!

Small size fruits

Restaurants and fruit-salad companies often pursue high productivity, which leads to high requirements when processing small-size fruits. The high-speed blade peeler already proved its performance in several kiwi factories in New Zeeland.

Why unique?

The blade peeler has so many advantages, but the round-type peeler is still the mainstream in the market. Peeling seems a simple performance, but it is the combination and balance of many elements such as the material of the blade (the metal used for some blades can only be produced in Japan), the shape of the peeler, the way it touches the fruit and the way it moves and speed control, etc. - all these factors play a role, and interact with each other.

The technological improvement behind the blade peeler is more than a simple change of the form of the blade. Most of the peeling machine manufactures know that blade peeling is much better, but they don’t have the experience and technology to make it real.

Over the past 20 years, ASTRA has been fully dedicated to automatic peeler innovation. ASTRA peeling machines are certified with CE and NSF markings, and are used in over 20 countries, including fresh-cut fruit factories, dried fruit factories, in-flight meals, hospitals, schools, juice bars, luxury cruise ships and restaurants.

As ASTRA Inc. expects the booming opportunity in the overseas markets, the company is now looking for distributors of industrial fruit processing machines in many areas.

For more information, please contact:

Ryo Takeshita

+81(0)24-541-2444