Fruit Control: New trends in horticultural produce storage and environmental sanitation

By Fruit Control

In the field of commodity storage and fresh produce, increasing attention is being aimed at some of the emerging aspects to which consumers are most sensitive.

The concept of shelf-life at one time was practically uninfluential on consumer choices, today, however, it has become a fundamental requirement for defining quality and preference for a determined product rather than another.

Nobody is interested in purchasing products that after just a few hours have started deteriorating to the point of being unusable. The same is valid for some storage treatments, an under-ripe vegetable product that cannot be consumed is of no interest to the final consumer.

Nowadays, the awareness aimed at obtaining an almost absolute guarantee of the absence of chemical residues and the elimination of preservatives for fruit and vegetables is not just a topic for specialists, but is a discussion in which housewives and consumers in general want to be active participants.

Moreover, nobody is prepared to give up those historically definable quality requisites such as: freshness, aesthetics, integrity, packaging appeal, branding and guaranteed origin. Without forgetting that, in these difficult times with the ongoing COVID-19 pandemic, another concept has become of prime importance: Safety.

Along the entire supply chain, from field to table, all the actors involved : farmers, shop-owners, all the different operators along the packing lines, haulers, and the consumer, all wait in turn to process, harvest, touch and finally, make their choice, in order to consume a safe, clean, product, protected from micro-organisms such as fungus, bacteria and virus.

This final goal, not easily reachable in absolute terms, but undoubtedly stimulating for who, in the horticultural field, intends having a pro-active role. Over the past ten years a large part of applied research has been orientated towards this theme in the post-harvest sector, both in Italy and abroad, involving those companies active in the same field that have been able to propose single and integrated technical solutions of noteworthy interest.

One of the main companies working on the world scene in the horticultural storage technology sector is FCE Fruit Control Equipments s.r.l. with their headquarters in Triulzi (Milan, Italy), which has fine-tuned recognized, effective technological proposals.

The company has realized post-harvest management and storage technology plants worldwide with the aim of maintaining quality, preservability and safety without needing to use chemical storage products and with attention regarding the lowest possible energy consumption.

Three particular currents have been successfully explored recently in the technological innovations that FCE. proposes to their customers:

- the storage of certain products (apples and pears mainly) in DCA. regime (Dynamic Controlled Atmosphere) with the aim of prolonging shelf-life and to control certain types of storage pathologies without resorting to chemical storage treatments.

- purification of the fruit & vegetable storage environments (cold rooms, technical corridors, packing/processing halls) from ethylene, a gaseous hormone that accelerates the maturation process and causes deterioration in many horticultural products.

- sanitation of the storage areas: cold rooms, loading-unloading bays, processing halls, storage areas from the presence of airborne fungus-bacteria-yeasts by carrying out continuous ionization treatment.

What is DCA and how is it effective? DCA is an evolution of CA (Controlled Atmosphere) where management of the gaseous parameters (O2 and CO2) is carried out, not by maintaining constant values, but by varying them over time and ranging from very low levels, close to zero, to higher, aerobic levels.

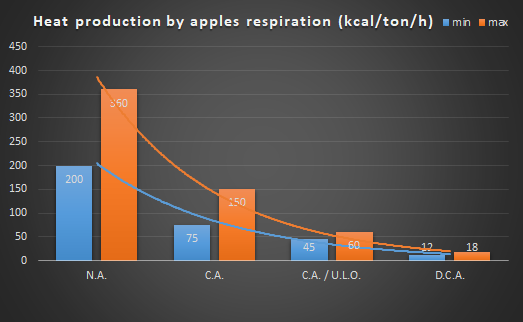

In these conditions, the fruit is maintained practically stable for over 10 months from harvesting, thanks to a drastic reduction in the respiratory levels and the natural qualitative decline that follows (see graph below)

These borderline conditions are managed by algorithms that use the metabolic signals from the stored fruit and are able to optimize management of all the components active in the plant installation (CO2 adsorbers-N2 generators, gas analysers etc) in complete automatism.

FCE reached this innovative proposal after many years of direct field experience and applied studies, that have given the company prestige and notoriety, obtained on the basis of actual positive results obtained by their customers.

Over time, other technological solutions have been added to DCA to be employed integrally. Among these is the development of an ethylene gas air purification system. In particular the storage and preservation, even for brief periods, of those species particularly sensitive to even low concentrations of ethylene such as kiwifruit, cut flowers, tropical fruits and certain vegetables, should be carried out in environments pratically free of the gas.

The system developed by FCE foresees purification/cleansing to almost zero levels, that is carried out by treating the air from the storage environment with catalytic combustion of even trace levels of ethylene.

Particular care during development of the BS PLATINUM converter (Fig. 3) allows up to 800mc/hour air to be cleansed using low energy consumption while remaining highly efficient and without modifying the treated air’s temperature, completely automatic, even remotely.

The achievable result is that of being able to maintain ethylene levels close to zero ppb with the result of managing to lengthen storability over time and likewise maintain the organoleptic and aesthetic qualities of the treated products.

The latest frontier among FCE’s applied technologies is the one regarding the current need for sanitation in environments where microorganisms can proliferate and attack fruit and vegetables: fungus-bacteria-yeast, and those that contaminate the air such as a virus. The method used is that of highly efficient and safe ionization (freed ions diffused into the air from a porous candle generator attack the microorganisms). IONNY, an apparatus that must be adequately sized for its setting. IONNY can be placed in any environment that requires low levels of microbiological contaminants (fungus, bacteria, yeasts, virus).

It has been demonstrated to lower the load of microorganisms by 70-80% in just a few hours (36-48) (see graph below) in all the environments where it has been placed (cold rooms, packing halls, loading bays etc.

The proven efficiency together with total safety for the employees working in those areas, as well as programmable function and management, make this technological solution one of the latest weapons with which to face the theme of environmental sanitation and for stored horticultural produce.

It is difficult to estimate the efficiency against viruses, but the salubrity of the workplace has been confirmed in several cases, even during this latest period, in warehouses and factories with a constant presence and high number of workers.

As can be deduced, FCE is able to propose high level and ground-breaking technology, to take on new challenges aimed at the results in terms of quality of the stored products, salubrity and food safety, sustainability and reduced energy consumption.

We can say, reasonably that integrated application of DCA, catalytic absorption and ionized sanitation certainly represent a high level of technology, up to the task of allowing, in the post-harvest phase of horticultural goods, definite goals to be reached….but maybe not yet completely explored.

FCE with their Italian-made products, demonstrate once again creativity and success.

For more information, please contact:

Dr. Luca Buglia

Email: info@fruitcontrol.it

Phone number: +39 029048141